Get Professional Help

Uncompromising Quality at JK Techno Forge

At JK Techno Forge, quality is at the core of everything we do. Our commitment to excellence ensures that every forged component meets the highest industry standards for durability, precision, and performance.

Quality Laboratory

Jk techno forge strives continously is improve its quality standards to statisfy the needs & expectations of the customers by establishing effective process control & prevention techniques and by supplying quality assured goods on time. Jk techno forge acquired with hardness tester M/C (to check the hardness of the parts),profile projector M/C (to verify the profile of turned parts), microscope (to analyze the micro – Structure of partstafter the Annealing process),ZEISS Contracer M/C (For inspection of radius, groove, chamfer, etc as per part/drawing requirements) in our quality lab. Which is satisfying customer the product – specific requirement.

We are also committed to enhancing our employee’s skills and implementing safety rules that affect the product quality.”

Our fully equipped work stations found throughout our casting and machining facility are an evidence of our commitment to Quality.

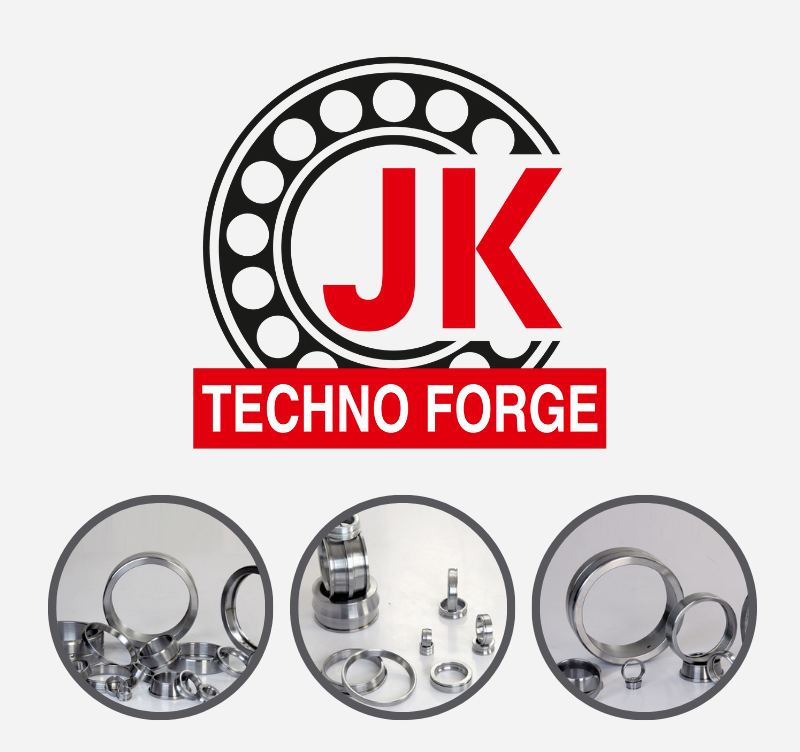

Final Products

Over last 3 decades has expertise the art of manufacturing high quality rings. The rings include ball bearings, Tapered Spherical and Cylindrical Rings. In addition to this the rings manufactured at stat-ofart production facility is capable ofproducing bearing components and spacers with operationsof drilling, turning and making.